Curious about how Microsoft shrunk its Surface devices while maintaining durability and premium quality? Many users searching for answers about the new Surface Pro 12-inch and Surface Laptop redesigns wonder how the tech giant balanced compact size with performance. During an exclusive visit to Microsoft’s Redmond headquarters, I explored the cutting-edge engineering behind these new devices, discovering the use of magnets, robots, drop tests, and intricate prototyping processes that ensure every Surface device meets high standards. Whether you're researching the Surface Pro hardware improvements or seeking insights into the Surface Laptop engineering upgrades, this behind-the-scenes journey answers it all.

Inside Microsoft's Surface hardware lab, innovation thrives. Engineers continuously test, iterate, and perfect every detail of their devices. For the new 12-inch Surface Pro and the redesigned Surface Laptop, Microsoft’s focus was crystal clear: shrink device size without sacrificing user experience, durability, or style. By using a combination of magnet technology, precision robotics, and sophisticated smoke tests, the Surface team refined every component, from the magnetic keyboard attachments to the Surface Slim Pen docking mechanism.

This effort highlights how Microsoft remains at the forefront of premium laptop engineering, consistently pushing the boundaries of tablet design and ultraportable computing.

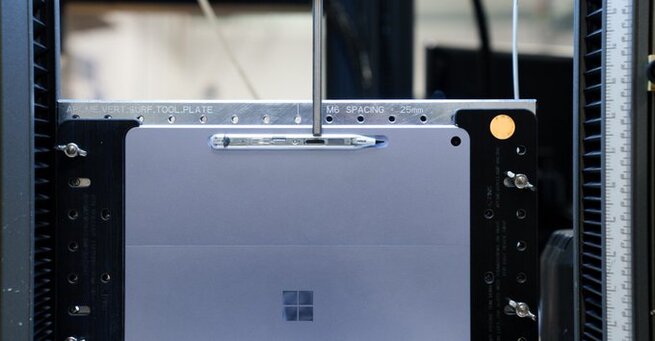

One of the more surprising challenges in shrinking the Surface Pro was perfecting the way the Surface Slim Pen attaches to the device. Microsoft engineers aimed for a simple one-handed attachment method while ensuring the pen stayed secure even during commutes inside a backpack.

To achieve this, they experimented with various magnet combinations, testing each setup with robots that precisely measured the force and angle needed to detach the pen. These data-driven refinements guaranteed a consistent, premium feel across all Surface Pro units, enhancing both usability and product longevity—two critical factors influencing laptop buyer decisions today.

Microsoft didn't stop with the pen. Engineers also focused heavily on perfecting the magnetic keyboard design and the Surface hinge mechanism. Each component underwent rigorous pass/fail testing, ensuring keyboards could attach securely at multiple angles and that hinges could survive repeated folding without degrading performance.

Such attention to detail pays off for professionals, students, and creators who demand high-performance laptops that are lightweight, durable, and versatile. By blending robust hardware engineering with sleek form factors, Microsoft’s new Surface models stand out in a crowded market increasingly favoring portable workstations and 2-in-1 tablets.

The extensive investment Microsoft puts into its hardware R&D is a clear reminder of how the company sustains its edge against competitors like Apple, Lenovo, and Dell. In a market where premium laptops and business tablets face growing scrutiny over quality and reliability, Microsoft’s Surface lineup benefits from obsessive engineering and advanced material testing.

This innovation-first approach aligns perfectly with rising trends in enterprise mobility solutions, digital transformation, and remote work technology, making Surface devices appealing not just to consumers but also to high-value enterprise clients.

𝗦𝗲𝗺𝗮𝘀𝗼𝗰𝗶𝗮𝗹 𝗶𝘀 𝘄𝗵𝗲𝗿𝗲 𝗿𝗲𝗮𝗹 𝗽𝗲𝗼𝗽𝗹𝗲 𝗰𝗼𝗻𝗻𝗲𝗰𝘁, 𝗴𝗿𝗼𝘄, 𝗮𝗻𝗱 𝗯𝗲𝗹𝗼𝗻𝗴. We’re more than just a social platform — from jobs and blogs to events and daily chats, we bring people and ideas together in one simple, meaningful space.